Scientists established a light yet strong product by integrating 2 unforeseen components– DNA and glass.

Operating At the nanoscale supplies researchers with a deep understanding and accuracy in crafting and examining products. In broader-scale production, and even in natural settings, many products are prone to flaws and impurities that can jeopardize their complex architecture. Such vulnerabilities can trigger them to fracture under pressure. This is especially apparent in the majority of kinds of glass, resulting in its track record as a vulnerable product.

Researchers at the Columbia University, the University of Connecticut, and the U.S. Department of Energy’s (DOE) Brookhaven National Lab had the ability to make a pure type of glass and coat specialized pieces of DNA with it to produce a product that was not just more powerful than steel, however extremely light-weight. Products that have both of these qualities are unusual, and more research study might result in unique engineering and defense applications. The outcomes were released in the journal Ce ll R eports Physical Science

DNA– The Foundation for Life and More

In living things, deoxyribonucleic acid, more frequently referred to as DNA, brings biological info that advises the cells of organisms on how to form, grow, and replicate. The product DNA is made from is referred to as a polymer, a class of difficult, flexible products that consists of plastic and rubber. Their strength and simpleness have actually captivated product researchers and influenced lots of intriguing experiments. Oleg Gang, a products researcher at the Center for Practical Nanomaterials ( CFN), a DOE Workplace of Science User Center at Brookhaven Laboratory, and a teacher at Columbia University, has actually been leveraging DNA’s special homes for products synthesis for many years, leading to many discoveries. This unique innovation has actually influenced a variety of ingenious applications– from drug shipment to electronic devices

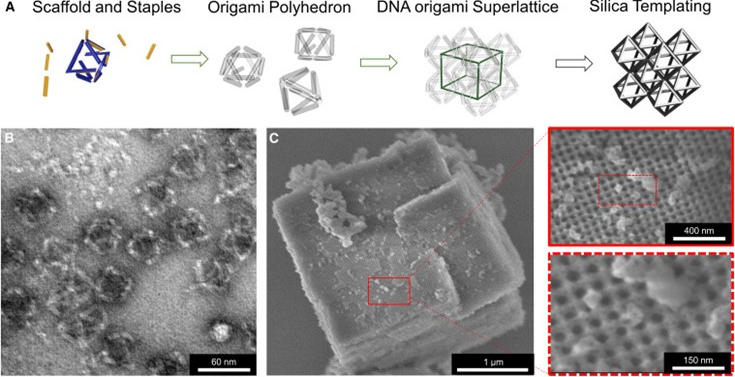

These blocks then stick together to form a bigger lattice– a structure with a duplicating pattern. This procedure permits researchers to develop 3D-ordered nanomaterials from DNA and incorporate inorganic nanoparticles and proteins, as shown by the group’s previous research studies. After acquiring an understanding and control of this special assembly procedure, Gang, Michelson, and their group were then able to explore what might be accomplished when that biomolecular scaffolding was utilized to produce silica structures that protect the scaffold architecture.

” We concentrated on utilizing DNA as a programmable nanomaterial to form a complicated 3D scaffold,” stated Michelson, “and we wished to check out how this scaffold will carry out mechanically when moved into more steady solid-state products. We checked out having this self-assembling product cast in silica, the primary active ingredient in glass, and its capacity.”

Michelson’s operate in this field made him the Robert Simon Memorial Reward at Columbia University. His research study into DNA structures has actually checked out a series of qualities and applications, from mechanical homes to superconductivity. Similar to the structures he’s built on, Michelson’s work continues to grow and develop as it handles brand-new layers of info from these amazing experiments.

A tiny peek of how these DNA hairs form shapes that are developed into bigger lattice structures that are covered in silica. CFN, JEOL-1400 TEM, and Hitachi-4800 SEM. Credit: Brookhaven National Lab

The next part of the fabrication procedure was influenced by biomineralization– the method particular living tissue produces minerals to end up being harder, like bones.

” We were really interested to check out how we can boost mechanical homes of routine products, like glass, however structuring them at the nanoscale,” stated Gang.

The researchers utilized a really thin layer of silica glass, just about 5 nm or a couple of hundred atoms thick, to coat the DNA frames, leaving inner areas open and making sure that the resulting product is ultra-light. On this little scale, the glass is insensitive to defects or flaws, offering a strength that isn’t seen in bigger pieces of glass where fractures establish and trigger it to shatter. The group wished to know precisely how strong this product was however, which, at this scale, needed some really specific devices.

Strength Under Pressure

There are basic methods to inspect if something is strong. Poking, pressing, and leaning on surface areas and observing their habits can frequently supply handy info. Do they flex, creak, buckle, or persevere under the tension? This is an easy, however reliable method to get an understanding of a things’s strength, even without tools to determine it exactly. How does one press on a things that’s too little to see, though?

” To determine the strength of these small structures, we utilized a strategy called nanoindentation,” discussed Michelson. “Nanoindentation is a mechanical test on a really little scale carried out utilizing an exact instrument that can use and determine resistive forces. Our samples are just a couple of microns thick, about a thousandth of a millimeter, so it’s difficult to determine these products by standard ways. Utilizing an electron microscopic lense and nanoindentation together, we can at the same time determine mechanical habits and observe the procedure of the compression.”

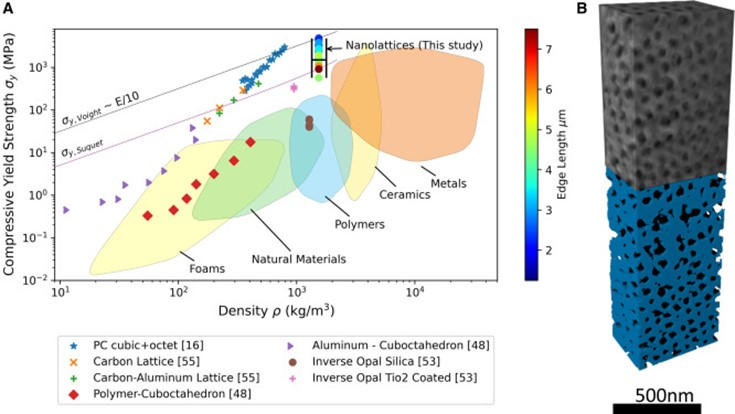

A chart comparing the nanolattice in this experiment to the relative strength of numerous products. Credit: Brookhaven National Lab

As the small gadget compresses, or indents, the sample, scientists can take measurements and observe mechanical homes. They can then see what occurs to the product as the compression is launched and the sample go back to its initial state. If there are any fractures that form or if the structure stops working at any point, this important information can be taped.

When tested, the glass-coated DNA lattice was revealed to be 4 times more powerful than steel! What was much more intriguing was that its density had to do with 5 times lower. While there are products that are strong and thought about relatively light-weight, it has actually never ever been accomplished to this degree.

This method wasn’t something that was constantly easily offered at CFN, nevertheless.

” We worked together with Seok-Woo Lee, an associate teacher at the University of Connecticut, who has proficiency in the mechanical homes of products,” stated Gang. “He was a CFN user who leveraged a few of our abilities and resources, like electron microscopic lens, which is how we established a relationship with him. We at first didn’t have the ability for nanoindentation, however he led us to the correct tools and got us on the best track. This is another example of how researchers from academic community and nationwide laboratories gain from collaborating. We now have these tools and the proficiency to take research studies like this even further.”

Structure Something New and Exciting

While there is still a great deal of work to be done prior to scaling up and considering the myriad of applications for such a product, there are still factors for products researchers to be thrilled about what this suggests moving forward. The group prepares to take a look at other products, like carbide ceramics, that are even more powerful than glass to see how they work and act. This might result in even more powerful light-weight products in the future.

While his profession is still in its early phases, Michelson has actually currently accomplished a lot and is currently excited to begin on the next stages of his research study.

” It’s a terrific chance to be a postdoc at Brookhaven Laboratory, specifically after being a Columbia College student who would operate at the CFN on a regular basis,” remembered Michelson. “This is what led me to continue there as a postdoc. The abilities that we have at the CFN, specifically in regard to imaging, truly assisted to move my work.”

Recommendation: “High-strength, light-weight nano-architected silica” by Aaron Michelson, Tyler J. Flanagan, Seok-Woo Lee and Oleg Gang, 27 June 2023, Cell Reports Physical Science

DOI: 10.1016/ j.xcrp.2023.101475