Modern fabrication tools such as 3D printers can make structural products fits that would have been hard or difficult utilizing standard tools. On the other hand, brand-new generative style systems can take fantastic benefit of this versatility to develop ingenious styles for parts of a brand-new structure, vehicle, or practically any other gadget.

However such “black box” automated systems frequently disappoint producing styles that are totally enhanced for their function, such as offering the best strength in percentage to weight or lessening the quantity of product required to support a provided load. Totally manual style, on the other hand, is lengthy and labor-intensive.

Now, scientists at MIT have actually discovered a method to attain a few of the very best of both of these methods. They utilized an automatic style system however stopped the procedure regularly to permit human engineers to assess the operate in development and make tweaks or changes prior to letting the computer system resume its style procedure. Presenting a few of these models produced outcomes that carried out much better than those developed by the automatic system alone, and the procedure was finished quicker compared to the totally manual method.

The outcomes are reported today in the journal Structural and Multidisciplinary Optimization, in a paper by MIT doctoral trainee Dat Ha and assistant teacher of civil and ecological engineering Josephine Carstensen.

The fundamental method can be used to a broad variety of scales and applications, Carstensen describes, for the style of whatever from biomedical gadgets to nanoscale products to structural assistance members of a high-rise building. Currently, automatic style systems have actually discovered numerous applications. “If we can make things in a much better method, if we can make whatever we desire, why not make it much better?” she asks.

” It’s a method to benefit from how we can make things in a lot more intricate methods than we might in the past,” states Ha, including that automated style systems have actually currently started to be extensively utilized over the last years in automobile and aerospace markets, where decreasing weight while preserving structural strength is an essential requirement.

” You can take a great deal of weight out of parts, and in these 2 markets, whatever is driven by weight,” he states. Sometimes, such as internal parts that aren’t noticeable, look is unimportant, however for other structures visual appeals might be very important too. The brand-new system makes it possible to enhance styles for visual along with mechanical residential or commercial properties, and in such choices the human touch is necessary.

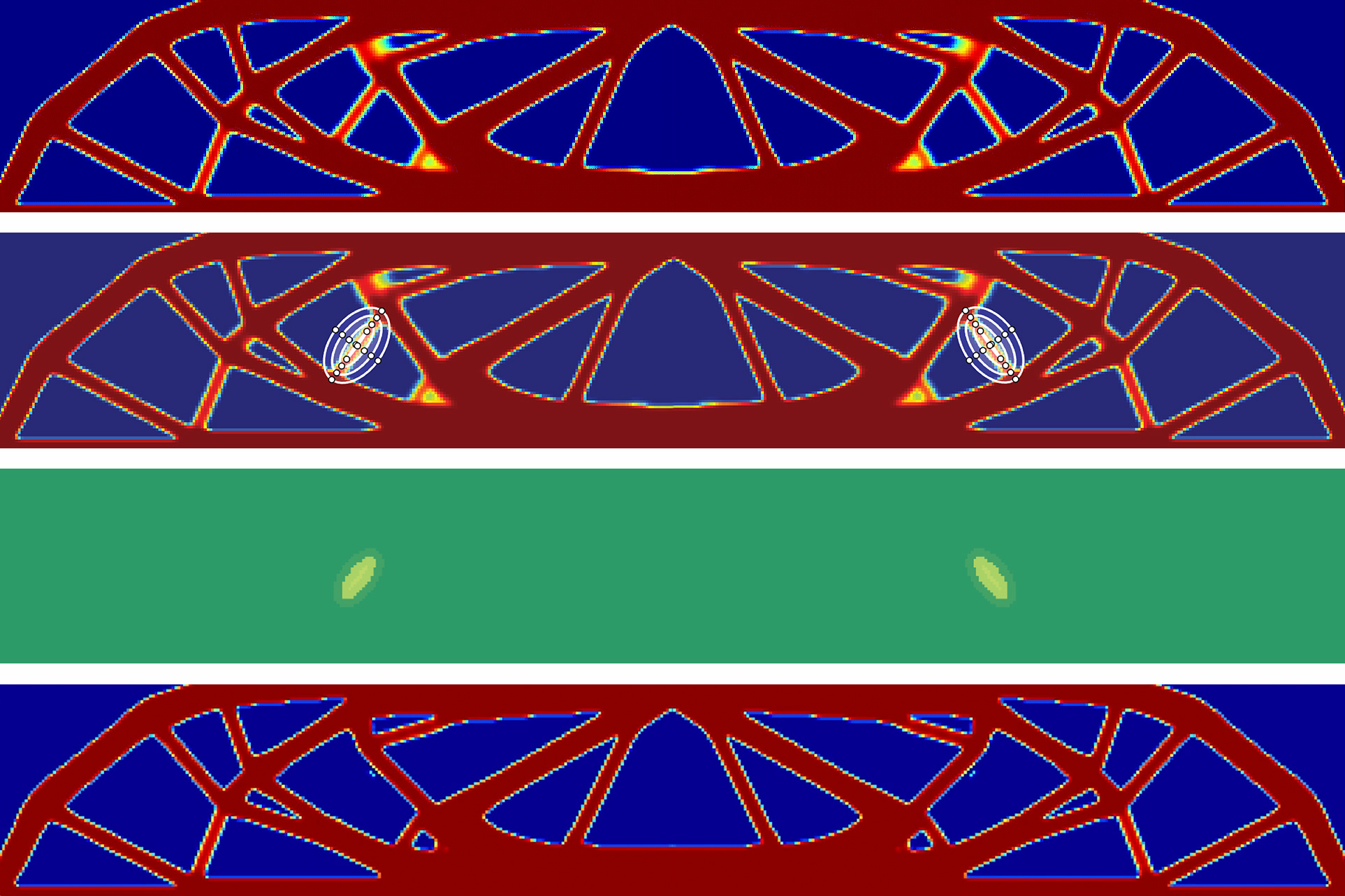

As a presentation of their procedure in action, the scientists developed a variety of structural load-bearing beams, such as may be utilized in a structure or a bridge. In their models, they saw that the style has a location that might stop working too soon, so they chose that function and needed the program to resolve it. The computer system then modified the style appropriately, eliminating the highlighted strut and enhancing some other struts to compensate, and causing an enhanced last style.

The procedure, which they call Human-Informed Geography Optimization, starts by setting out the required requirements– for instance, a beam requires to be this length, supported on 2 points at its ends, and should support this much of a load. “As we’re seeing the structure develop on the computer system screen in action to preliminary spec,” Carstensen states, “we disrupt the style and ask the user to evaluate it. The user can choose, state, ‘I’m not a fan of this area, I ‘d like you to boost or beef down this function size requirement.’ And after that the algorithm considers the user input.”

While the outcome is not as perfect as what may be produced by a totally extensive yet substantially slower style algorithm that thinks about the underlying physics, she states it can be better than an outcome produced by a fast automatic style system alone. “You do not get something that’s rather as great, however that was not always the objective. What we can reveal is that rather of utilizing a number of hours to get something, we can utilize 10 minutes and get something better than where we began.”

The system can be utilized to enhance a style based upon any wanted residential or commercial properties, not simply strength and weight. For instance, it can be utilized to reduce fracture or buckling, or to decrease tensions in the product by softening corners.

Carstensen states, “We’re not seeking to change the seven-hour option. If you have all the time and all the resources worldwide, certainly you can run these and it’s going to offer you the very best option.” However for numerous circumstances, such as developing replacement parts for devices in a battle zone or a disaster-relief location with minimal computational power readily available, “then this sort of option that catered straight to your requirements would dominate.”

Likewise, for smaller sized business making devices in basically “mommy and pop” organizations, such a streamlined system may be simply the ticket. The brand-new system they established is not just easy and effective to work on smaller sized computer systems, however it likewise needs far less training to produce beneficial outcomes, Carstensen states. A fundamental two-dimensional variation of the software application, ideal for developing fundamental beams and structural parts, is easily readily available now online, she states, as the group continues to establish a complete 3D variation.

” The possible applications of Prof Carstensen’s research study and tools are rather remarkable,” states Christian Málaga-Chuquitaype, a teacher of civil and ecological engineering at Imperial College London, who was not connected with this work. “With this work, her group is leading the way towards a really synergistic human-machine style interaction.”

” By incorporating engineering ‘instinct’ (or engineering ‘judgement’) into a strenuous yet computationally effective geography optimization procedure, the human engineer is used the possibility of assisting the production of ideal structural setups in a manner that was not readily available to us previously,” he includes. “Her findings have the possible to alter the method engineers take on ‘everyday’ style jobs.”